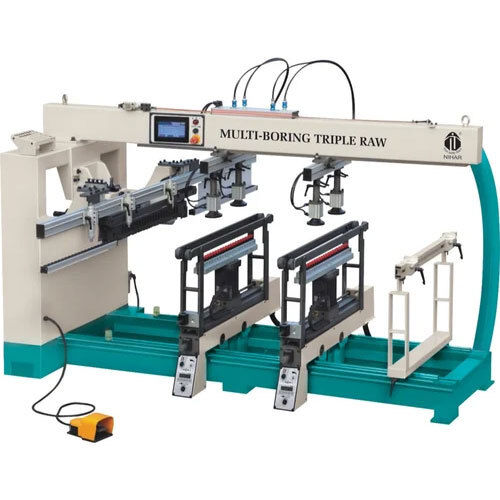

Multi Boring Triple Raw Machine

Multi Boring Triple Raw Machine Specification

- Power Source

- Electricity

- Operating Type

- Automatic

- Surface Treatment

- Painted

- Warranty

- Yes

- Usage & Applications

- Industrial

Multi Boring Triple Raw Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 30 Days

- Main Domestic Market

- All India

About Multi Boring Triple Raw Machine

Multi Boring Triple Raw Machine is an industrial woodworking equipment used for drilling holes in wood boards or panels. It is engineered to efficiently and accurately drill multiple holes simultaneously in a single operation. The machine consists of multiple drill heads arranged in three rows, which allows for increased versatility and productivity. Multi Boring Triple Raw Machine is widely used in industries such as cabinet making, furniture manufacturing, and woodworking workshops. This machine is ideal for tasks that require precise hole patterns, such as dowel holes, shelf pin holes, or hardware installation holes. This machine helps woodworkers significantly speed up the drilling process while maintaining consistency and accuracy.

Specification

|

Description |

NR 153 3R |

NR 153 3R Plus |

|

Max. Width of Work Piece (X Direction) |

1850 mm |

2450 mm |

|

Max. Distance of Two Horizontal Boring Position |

640mm mm |

640 mm |

|

Min. Distance of Vertical Drilling Group |

128 mm |

128 mm |

|

Max. Thickness of Work Piece |

78 mm |

78 mm |

|

Max. Depth of Horizontal Boring Head |

40 mm |

40 mm |

|

Max. Depth of Vertical Boring Head |

70mm |

70mm |

|

Rotating Speed of Boring Spindles |

2800 RPM (50Hz) |

2800 RPM (50Hz) |

|

Vertical Boring Power |

1.5 KW+1.5 KW |

1.5 KW+1.5 KW |

|

Horizontal Boring Power |

1.5 KW |

1.5 KW |

|

Working Pressure |

0.6-0.8 Mpa |

0.6-0.8 Mpa |

|

Power |

4.5 KW / 415V /50 Hz |

4.5 KW / 415V /50 Hz |

FAQs of Multi Boring Triple Raw Machine:

Q: What is the operating type of the Multi Boring Triple Raw Machine?

A: The operating type is automatic.Q: What is the power source for the Multi Boring Triple Raw Machine?

A: The power source is electricity.Q: What is the surface treatment of the Multi Boring Triple Raw Machine?

A: The surface treatment is painted.Q: What is the warranty for the Multi Boring Triple Raw Machine?

A: Yes, it comes with a warranty.Q: What is the intended usage or application of the Multi Boring Triple Raw Machine?

A: It is designed for industrial use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Multi Boring Machine Category

Industrial Multi Boring Single Raw Machine

Minimum Order Quantity : 1 Unit

Power Source : Electricity

Usage & Applications : Industrial

Operating Type : Automatic

Warranty : Yes

Triple Raw Head Multi Boring Machine

Price 695000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Power Source : Electricity

Usage & Applications : Industrial

Operating Type : Automatic

Double Raw Multi Boring Machine

Price 475000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Power Source : Electricity

Usage & Applications : Industrial

Warranty : 1 Years

Single Head Multi Boring Machine

Price 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Power Source : Electricity

Usage & Applications : Industrial

Operating Type : Automatic

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS